ECI Elastic unveils eco-friendly mechanical stretch tape

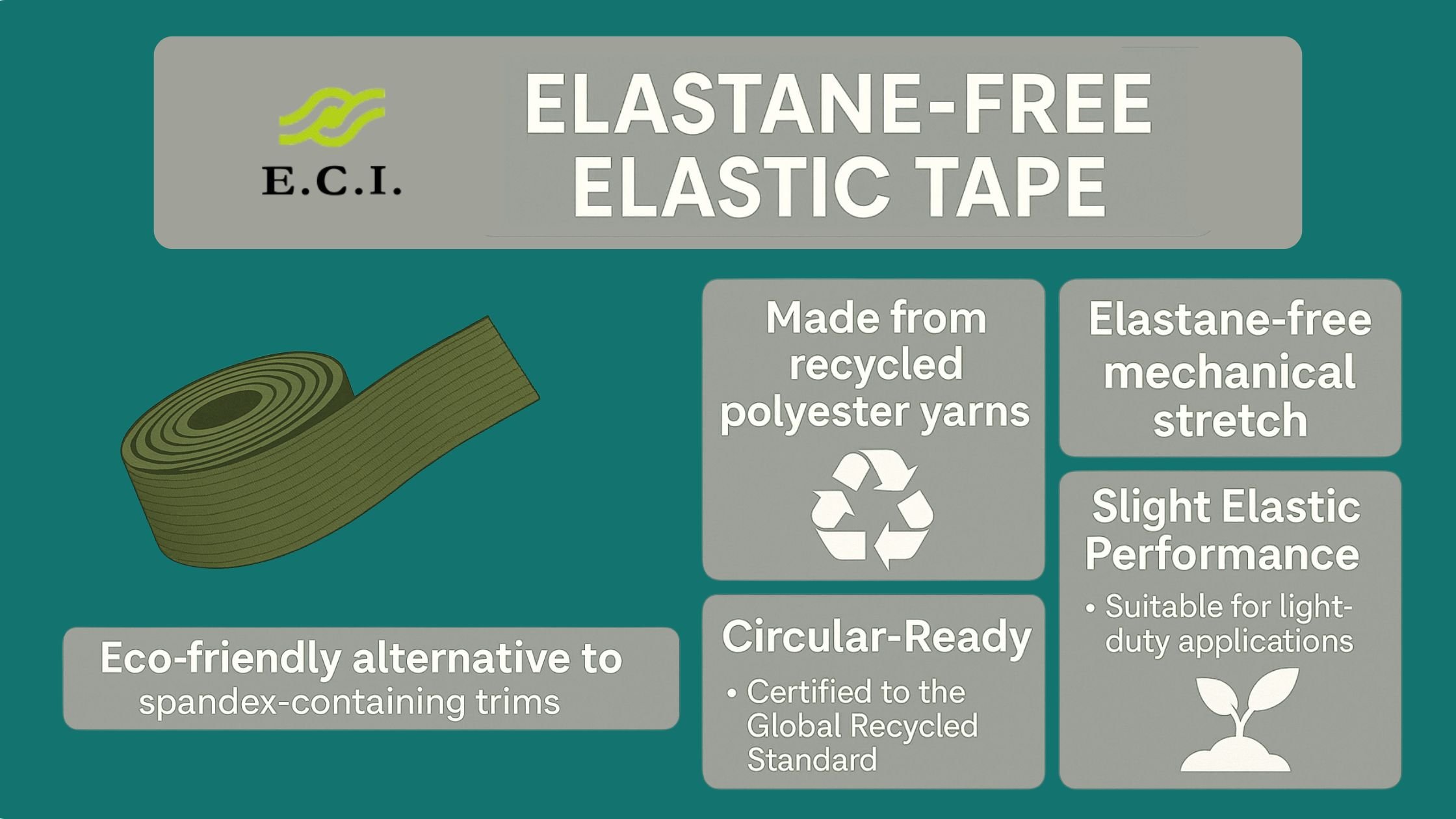

ECI Elastic, a global leader in narrow fabric elastic solutions, has announced the launch of its new mechanical stretch tape, ECI#3B46N. This tape was developed as a sustainable alternative to spandex-added elastic trims in apparel. This innovation marks a step forward in ECI’s ongoing efforts to offer responsible material options that meet the evolving needs of sourcing and sustainability teams across the textile and fashion industry. While elastane (spandex) remains a valuable material for achieving high levels of stretch in performance apparel, it also presents recycling and end-of-life challenges. Even small amounts of elastane can limit the recyclability of garments, especially when blended with other fibers. As brands seek more circular solutions and reduce complexity in material compositions, innovations like ECI#3B46N offer practical alternatives in areas where only moderate elasticity is needed.

Made from Global Recycled Standard (GRS)-certified recycled polyester yarns, ECI#3B46N provides slight elastic performance without any elastane content. Ideal for use in back neck tapes, decorative and binding tapes, fold-over elastic applications, and light-duty trims, the new tape maintains functional performance. It is fully polyester-based, making it a better match for mono-material garments designed with recyclability in mind. Internal testing has confirmed that ECI#3B46N delivers a comparable feel and stretch recovery to conventional light elastics, at a cost point suitable for mass-market applications. Unlike traditional elastic tapes that blend elastane with nylon or polyester, this tape simplifies material profiles—an increasingly important factor for brands working to meet recycling standards and circularity commitments. ECI Elastic plans to scale up production of this new tape by Q4 2025 to support broader adoption by apparel and footwear brands integrating sustainable components across their lines. This development builds on ECI Elastic’s broader sustainability roadmap, which includes using recycled content across a growing range of trims and incorporating low-impact manufacturing practices. The company’s portfolio now includes recycled jacquard elastics as well as waste-yarn-based fancy trims.